Autonomous Maintenance in Practice

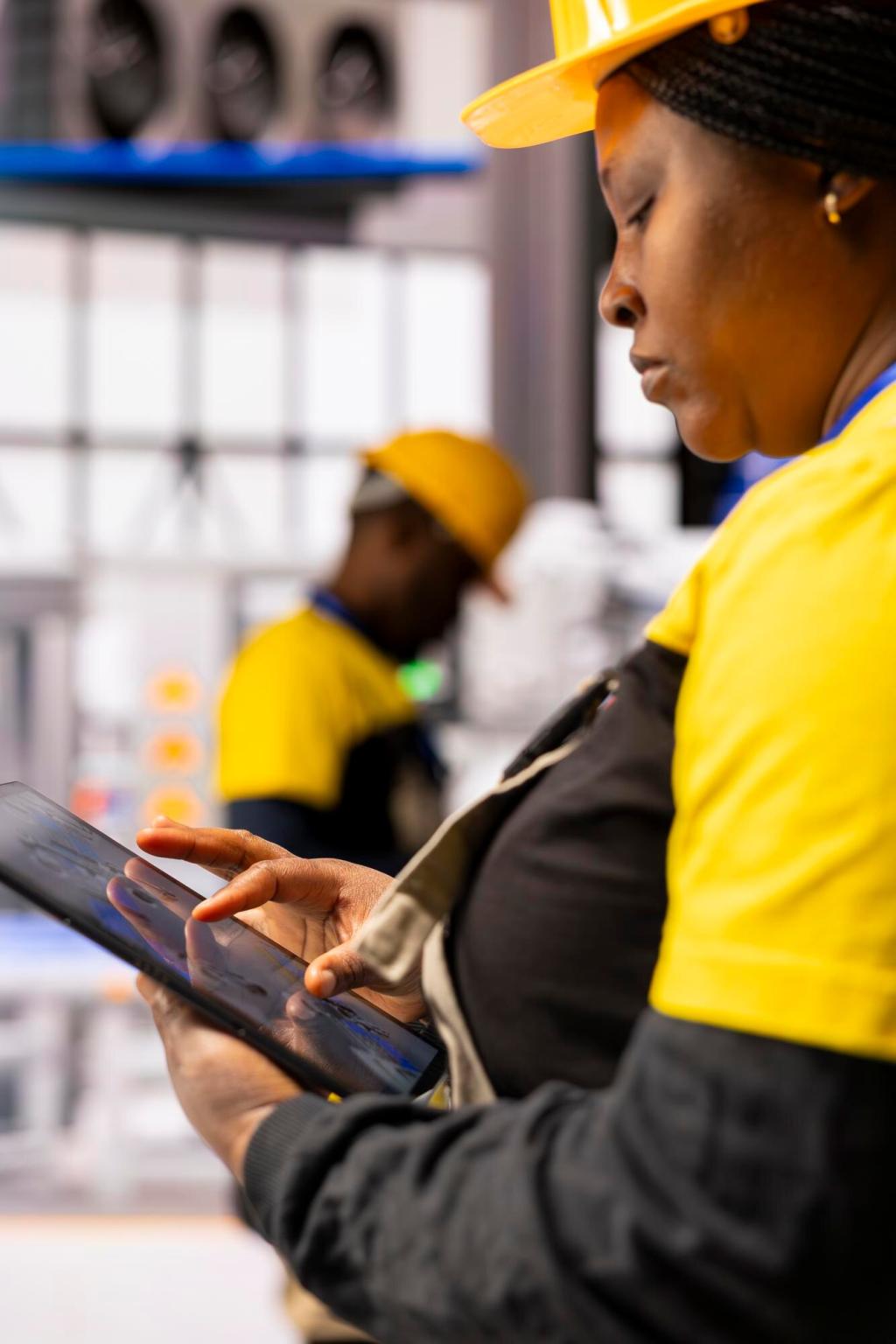

A bakery line introduced five-minute end-of-shift wipe-downs with bright flashlights. Within two weeks, operators found loose guards and oil mist patterns that predicted a failing seal. Cleaning stopped being a chore and became detective work. Try it and tell us what patterns your team starts to notice.

Autonomous Maintenance in Practice

Red, yellow, and green tags helped a beverage plant separate critical issues from routine ones. Visual tags triggered swift triage in tier meetings and built trust between ops and maintenance. Start a simple tag board, review daily, and comment with your best tip for keeping the board honest.

Autonomous Maintenance in Practice

Clear, photo-rich standards for lubrication, belt tension, and filter checks let operators own safe, low-risk tasks. Result: fewer emergency calls, calmer weekends for technicians, and faster starts on Mondays. Want our sample one-point lessons template? Subscribe and we’ll send the editable version straight to your inbox.