Turn Chaos into Flow: Value Stream Mapping for Manufacturers

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Getting Started: Current-State Mapping Done Right

Go to the Gemba and Walk the Order

Start on the floor, following a real customer order from intake to shipment. Time the steps, note waiting, count WIP, and listen to the people who touch the process every day.

Find the Pacemaker and Calculate Takt

Choose a pacemaker process that best reflects customer demand, then compute takt time by dividing available production time by average demand. Use it to synchronize processes and stabilize schedules upstream.

Pull Systems, Supermarkets, and FIFO

Replace push and guesswork with visual pull. Right-size supermarkets, define kanban quantities, and install FIFO lanes where variability risks starving or flooding critical steps.

Metrics That Matter in Value Stream Mapping

Lead Time versus Processing Time

Lead time includes every hour the order waits. Processing time covers only hands-on work. Value Stream Mapping exposes the gulf between them, redirecting attention toward queues, setups, approvals, and transport delays.

Flow Efficiency and First-Time-Through

Flow efficiency compares touch time to total lead time, often revealing single-digit performance. Combine it with first-time-through to spotlight where defects and rework quietly erode capacity and customer trust.

Capacity, Variability, and Reliability

Use data on uptime, changeover, and lot sizes to understand true capacity under variability. Stabilize with maintenance, buffering, and leveling before chasing costly equipment that may not fix the real constraint.

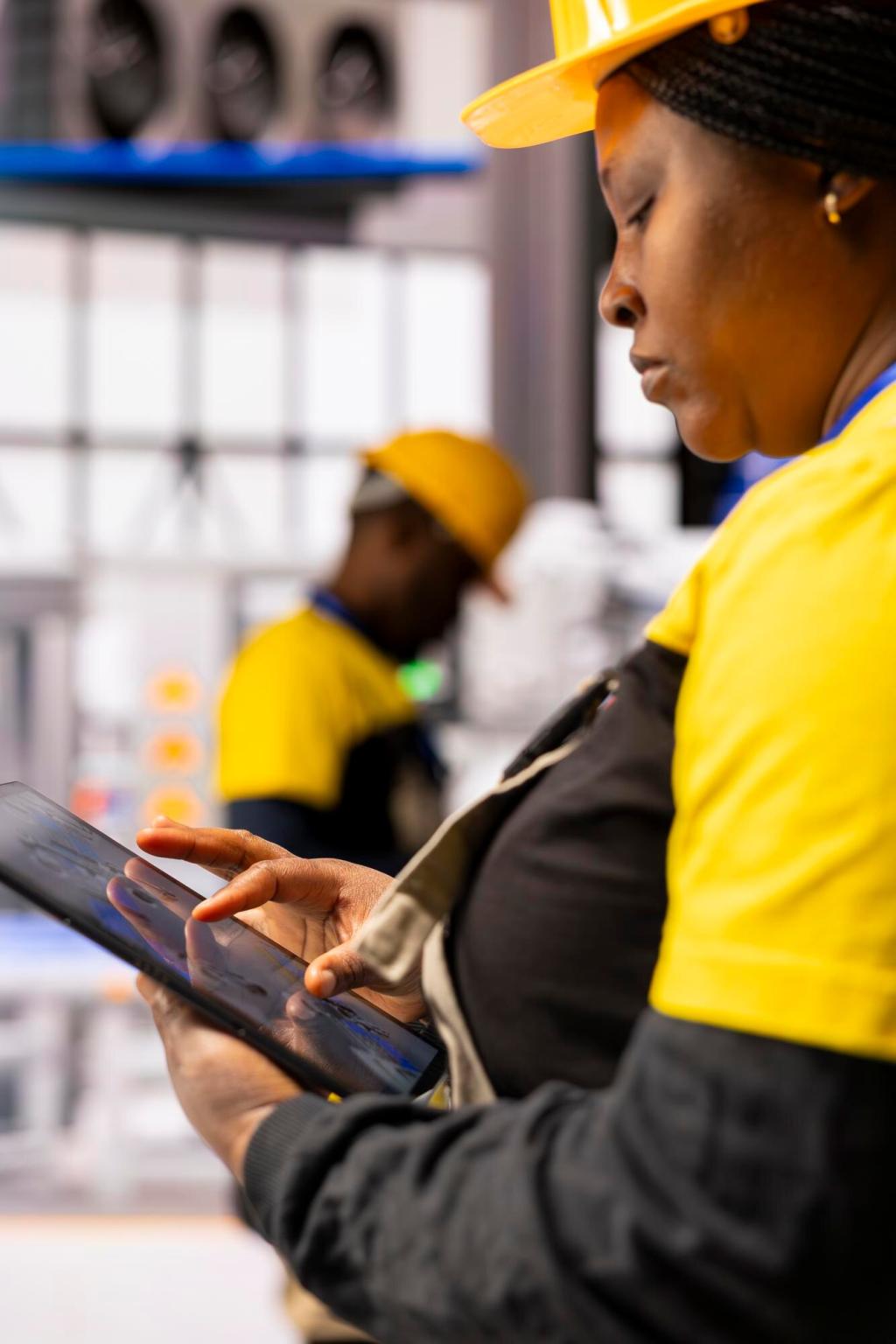

Make It Stick: Engaging People Around the Map

Hold short standups at the map, reviewing yesterday’s flow against takt, WIP limits, and blockers. Invite operators to flag issues and own rapid experiments, then capture learnings directly on the map.